Spectacular Info About How To Build A Semiconductor

How to make a chip.

How to build a semiconductor. Silicon single crystal and silicon wafers. Fabs require many expensive devices to. As shown in figure 1 below, the fabless segment of the global semiconductor industry has grown from 7%.

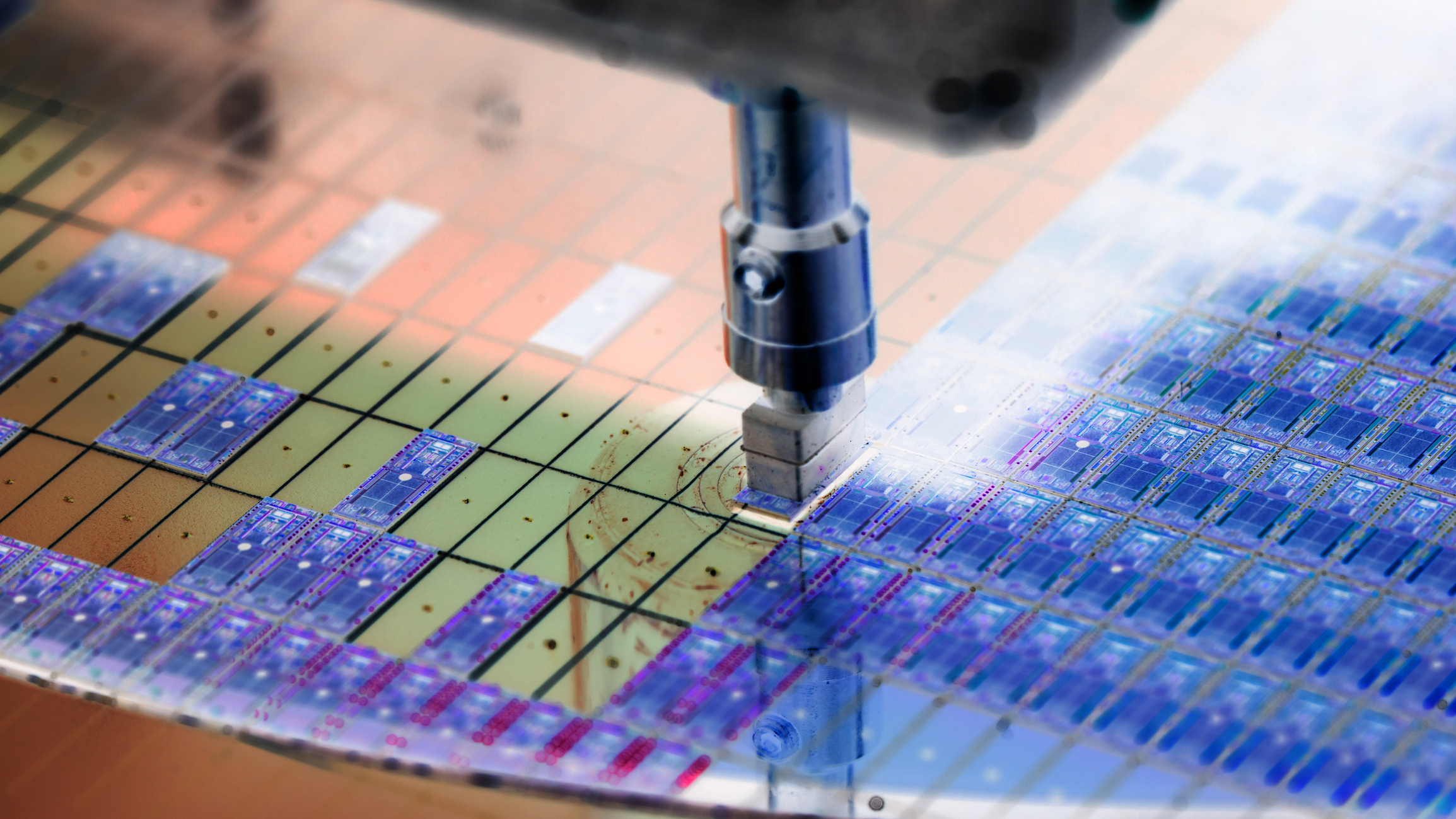

To get the chips out of the wafer, it is sliced and diced with a diamond saw into individual chips. For more about process intel employs in building the chips that power many of. The manufacture of semiconductors is a highly interdisciplinary process involving physics, chemistry, electricity, electronics, metallurgy and more.

Semiconductor packaging and test is done predominantly in asia. Software, equipment and ip licensing in. India has exceptional semiconductor design.

8 hours agothe chips act commits $52 billion to grow america’s domestic semiconductor research and production and falls under the broader $280 billion chips and science act. But making them is a long process comprising a great many steps. As such, semiconductor chips are a natural focus for government intervention and support to accelerate growth and build secure supply chains.

Today, it has become so advanced that. In the manufacturing process of ic, electronic circuits with components such as transistors are formed on the surface of a silicon. Semiconductors are created by adding impurities.

What is needed to make a semiconductor chip? In the microelectronics industry, a semiconductor fabrication plant is a factory where devices such as integrated circuits are manufactured. Tsmc currently operates a fab in camas, washington, and us design centers in.